china vertical centrifugal sump pump factories

Latest articles

If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreSlurry Pump

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreSlurry Pump

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreCentrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreThe Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreSelecting a dredge pump

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreDepending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreChoosing the Right Pump for Flue Gas Desulphurisation

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read MoreA target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

china vertical centrifugal sump pump factories...

china vertical centrifugal sump pump factories 【china vertical centrifugal sump pump factories】

Read More

Popular articles

- What are the materials used to construct the pump?

- What is the optimum seal arrangement for the application?

- The concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Another important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

Latest articles

-

>Slurry Pump

-

The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

-

Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

-

WA Heavy-duty Slurry Pump

-

Rubber lined pumps offer many advantages

-

Auxiliary equipment

Links

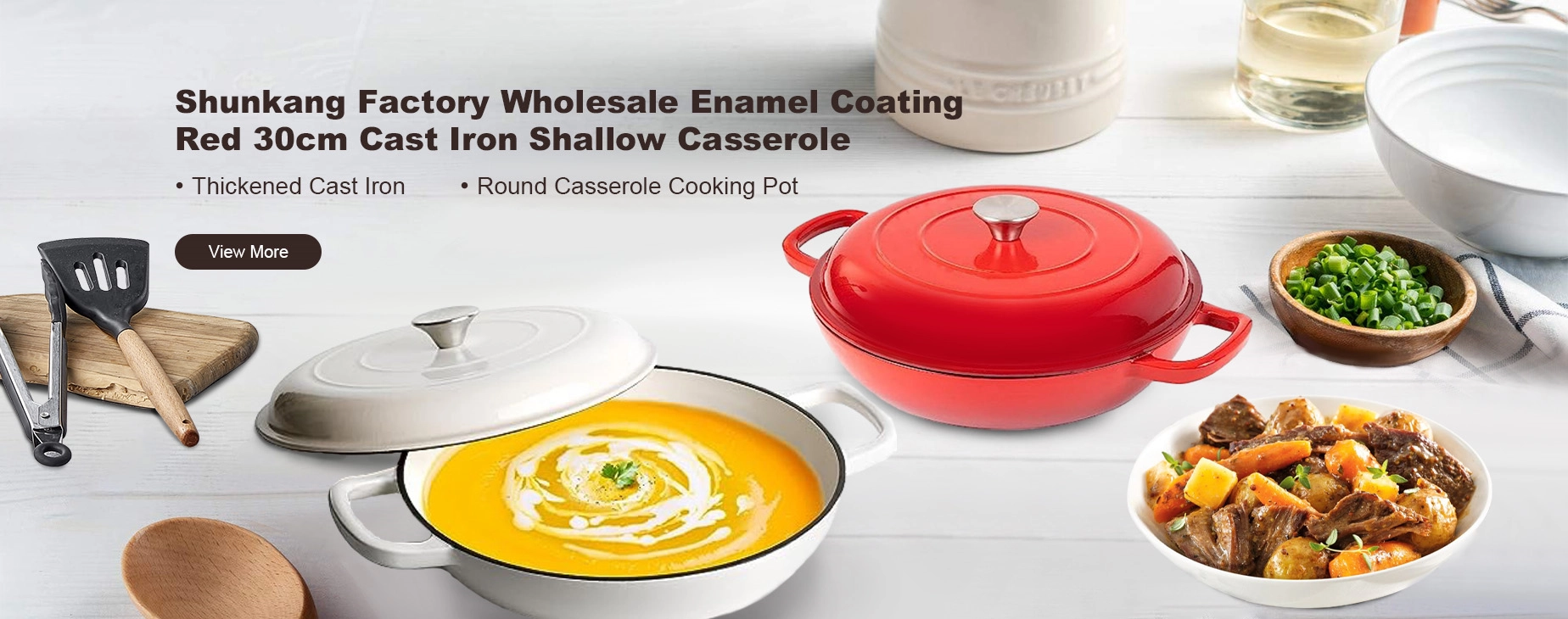

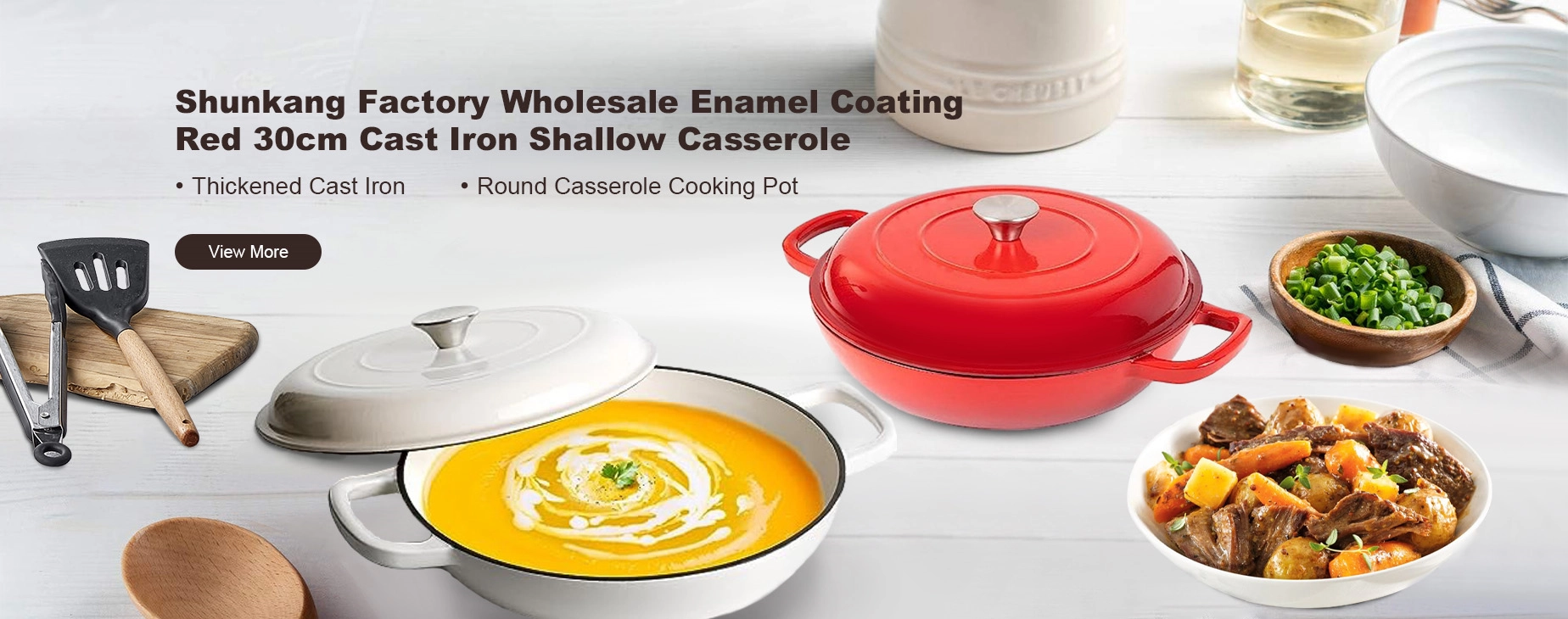

Interactive Presentation: The sizzle and steam emanating from the hot plate or platter create an interactive and sensory dining experience, engaging diners and adding an element of excitement to the meal presentation.

With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions

With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions griddle grill cast iron.

griddle grill cast iron.Do chefs use non-stick cookware?

Washing Cast Iron Griddle

The cooking vessels are used similarly to frying pans, mainly because they can hold more liquid.

Ordinary people will have difficulty identifying the difference between a skillet and a frying pan. Some people use the two names interchangeably, others believe there is a significant distinction. Skillets and frying pans are not the same things, despite popular belief.

cast iron grill pan with detachable handle. This feature is especially helpful for those with limited storage space in their kitchen.

While on the other side, we have the skillet which is best for cooking food at high heat such as searing, reducing, sauteing, and shallow frying. That’s because of its common construction of cast iron or stainless steel, which causes slow and even heat distribution but excellent heat retention.

Best for: Scrambled or fried eggs, pancakes, fish, grilled cheese, and any other food that has a high probability of sticking to a typical pan. With nonstick skillets, these foods slide easily from frying pan to plate.

Avoid using metal utensils to prevent scratches, and always dry thoroughly to prevent rusting Avoid using metal utensils to prevent scratches, and always dry thoroughly to prevent rusting

Avoid using metal utensils to prevent scratches, and always dry thoroughly to prevent rusting Avoid using metal utensils to prevent scratches, and always dry thoroughly to prevent rusting iron enamel cookware.

iron enamel cookware.